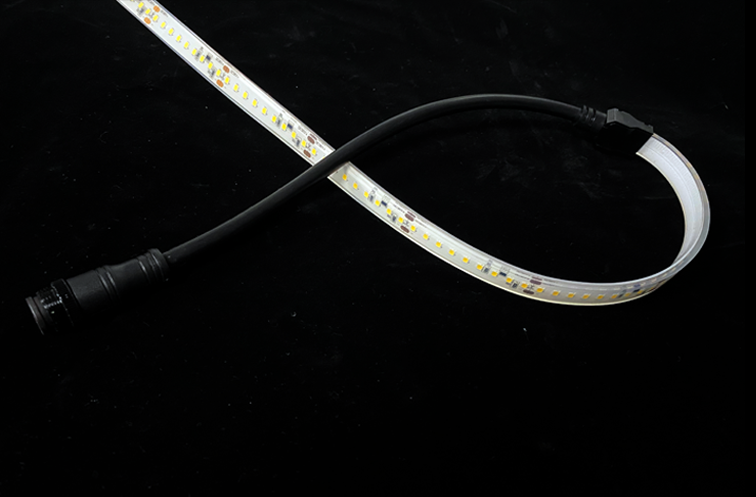

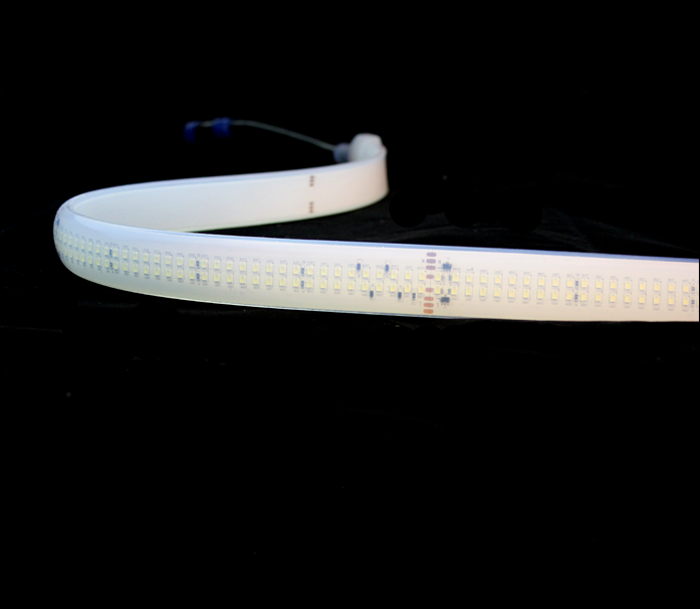

The new designs incorporate cluster management technology, whereas the LEDs are fixed onto PCB boards forming clusters which are then welded together and extruded in a food grade silicone to form the actual strip lighting, these PCB boards are connected in parallel with the electrical circuit working together in synergy as a lighting platform, but independently in the unlikely case of failure, this means if there is a failure on any components of the lighting it would be isolated and not affect the remaining lighting system.

9 Benefits of LED Strips

LED strip lights have revolutionized the lighting world. From being highly efficient to longer life cycles the benefits of LED strips is one of today’s technologies breakthroughs. A led strip light is a flexible circuit board of LEDs that can be mounted to virtually any surface that you’re looking to add influential lighting. LED strips are available in a range of colors and brilliance.

Adjustable

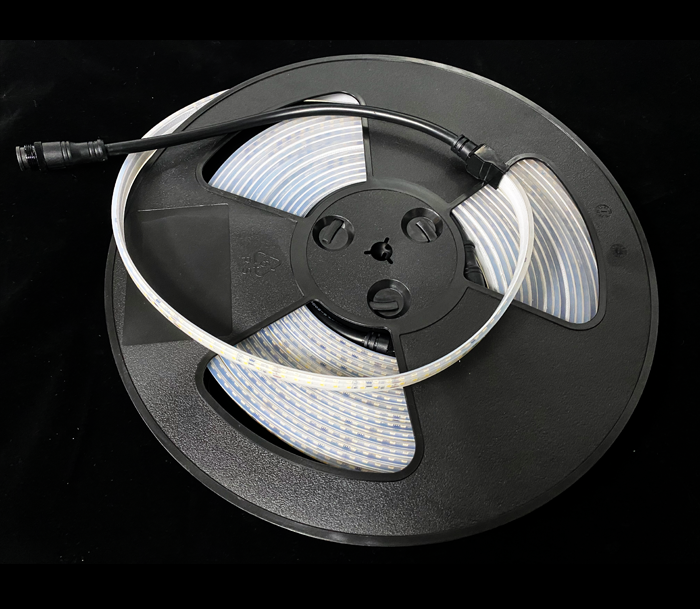

LED strips can be cut to any length. From cutting the strip a few inches to several feet, you can customize the length on any LED strip to fit the exact needs of your project.

Flexible

LED strips can be curved vertically up to 45 degrees. With LED light strips you can install them in places that were previously inaccessible.

Best Color Variety

LED strips are available in any tone white all the way up to any color. Using RGB LED strip lights and a controller you can set and control the exact color and brightness.

Super Thin

LED strips are only 4mm thick making them easy to install in tight areas and you can easily hide the LED strips from plan-view.

Easy To Install

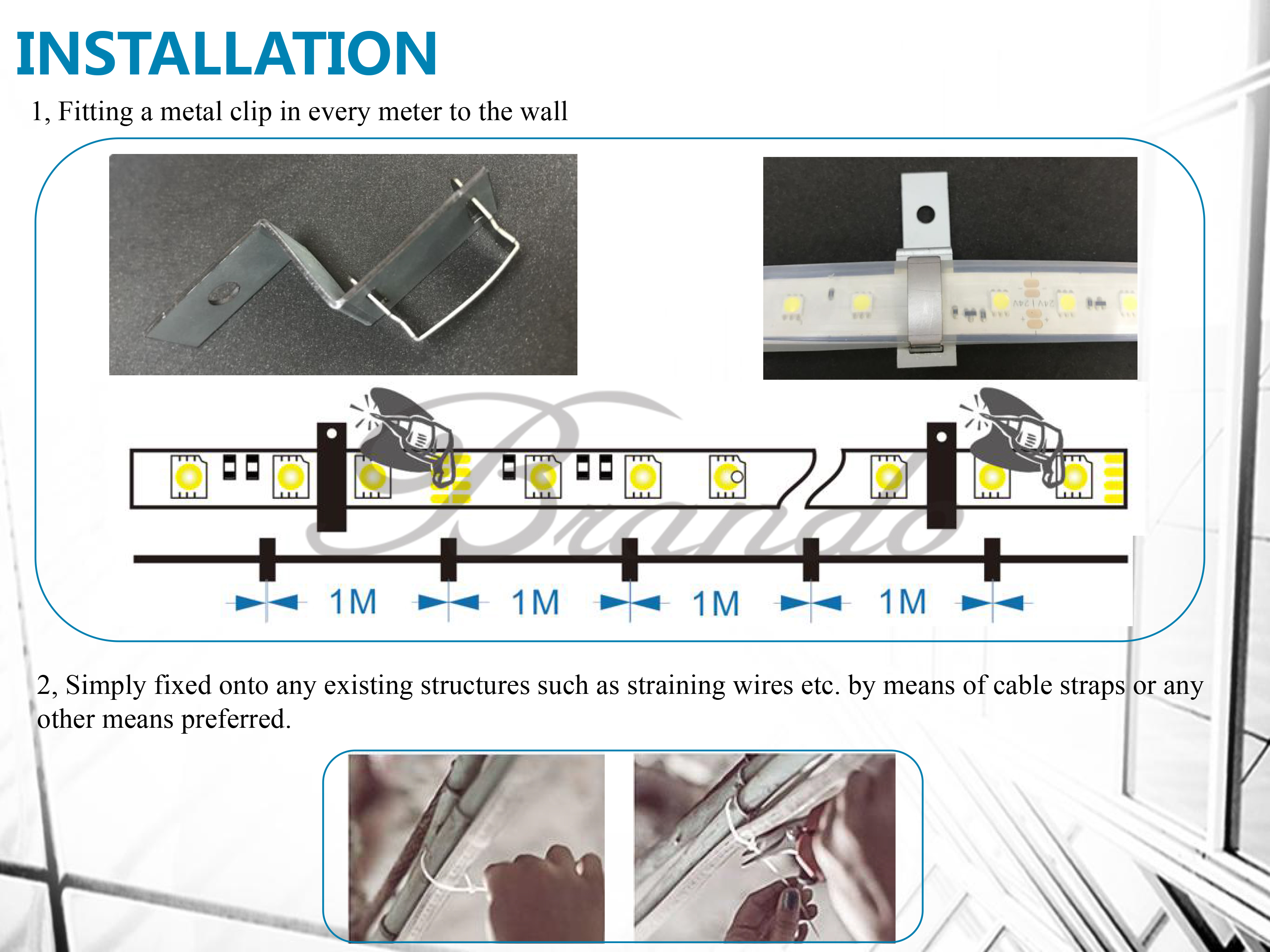

LED strip lights come with cable ties, plastic or metal clips making it easy to attach the lights to a wide variety of surface.

Dimmable Lighting

LED strip lights can be dimmed using home lighting systems, DMX and dimming controllers, and remote controls. This allows you to set the perfect mood!

Safe

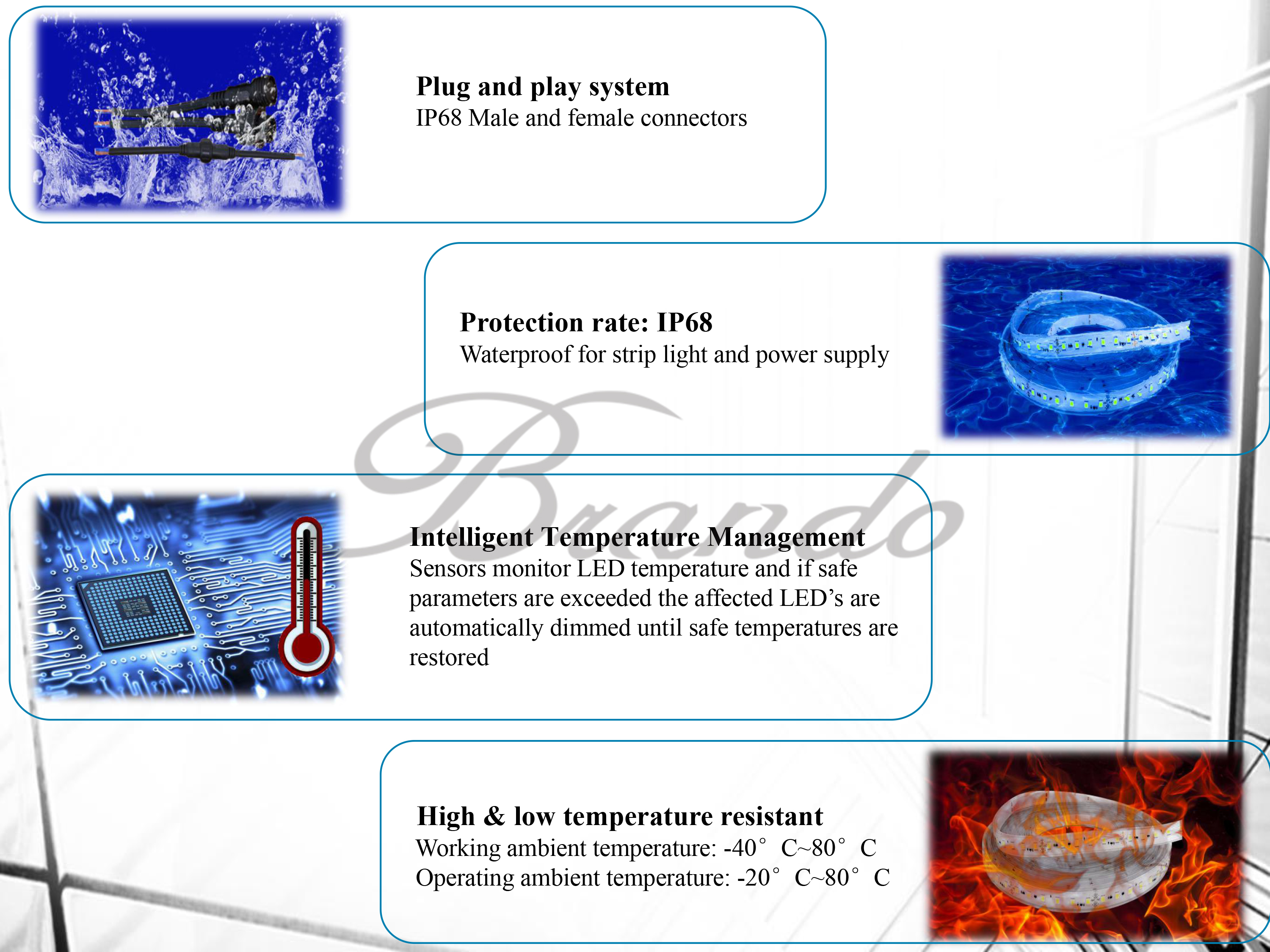

Look for IP67, and IP68 rating for dust and waterproof resistant LED strip lights.

Custom

With LED strip lights you have full control over the color, length, CRI, brightness, and voltage.

Lower Cost of Ownership

LED strips to use 50% less energy than traditional fluorescent, incandescent, and halogen lights. This savings in energy equates to a small energy bill. Also, the average LED strip lasts 50,000 hours keeping the need for a replacement for every 5-10 years.

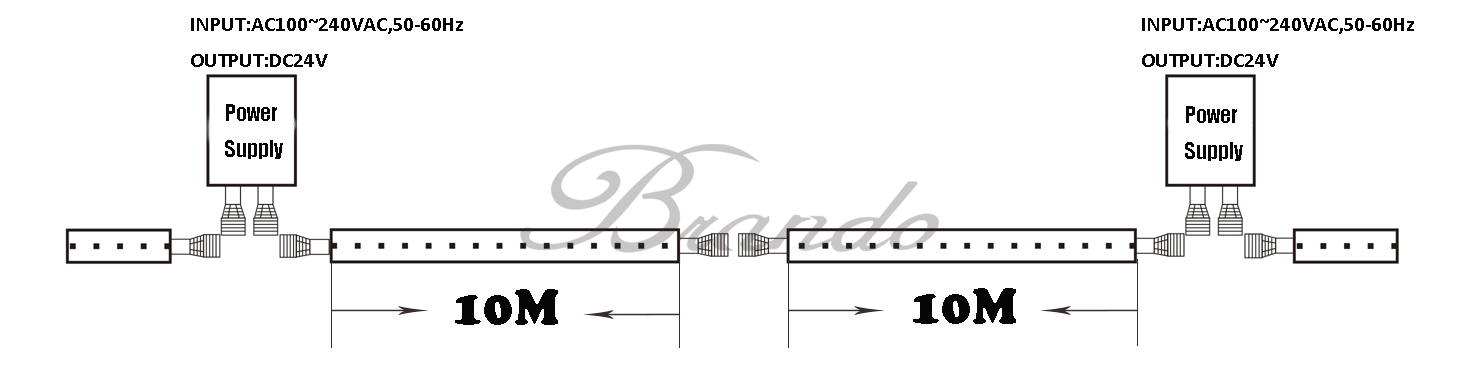

Plug and play system

Conventional lighting requires separate power and a wired connection to every lamp, needing the expertise of electricians. This becomes labour-intensive and costly when running many meters of lighting. The BRANDO LED Strip Lighting plugs into an existing power source using a power supply which then connects to one end of the LED strip. A single power supply will light a 20 meter LED section. To extend beyond 20 meters, just add another power supply at the other end and connect the next section of LED strip – it's that simple.

Maintenance-free. Easy to repair.

Damage to lighting through routine underground activities happens. When a conventional lamp is damaged, it results in loss of illumination over many meters – making the affected area a safety hazard until repaired by a qualified electrician. Should a section of the BRANDO strip light be damaged, only this section loses light. The remaining portion of the strip continues to provide illumination – allowing for a safer environment. Additionally, damaged sections can be replaced in 8" strips – making it a quick and cost-effective fix.

• Intelligent temperature management, sensors monitor LED temperature and if safe parameters are exceeded the affected LED’s are automatically dimmed until safe temperatures are restored.

• Intelligent voltage surge management, restorable resistors limit overcurrent and overvoltage situations.

• AC to DC convertors, miniature voltage convertors.

• Short circuit protection, in the case of short circuit the power is isolated until the circuit is normalized.

| Part Number | BO-SL120-15W-24V(B) |

| LED Chip | Epistar |

| LED configuration | 120 LED's spaced evenly over a metre length |

| Range fed from both sides | 20 metres |

| Recommended fixing height | 5 - 6 Metres |

| IP Rating | 68 |

| Power Consumption per LED | 0.125 Watts |

| Power Consumption per Metre | 15 Watts |

| Colour Rendering Index CRI | > 80 |

| Colour temperature | 6500 Kelvin |

| Luminous Efficacy | 90 Lumens / Watt |

| Voltage on lighting VDC | 24 VDC |

| Supply voltage for power controllers VAC | 85 - 265 VAC |

| Light maintenance | 15%-20% Drop over 4 years |

| Lifespan | 5 Years + |

| Warranty Lighting | 1 Years |

| Outer covering | Food grade silicone |

| Dimensions | 10000mm(length) *14mm(width) *4mm(height) |

| Tensile strength | +-50KG |

| Operating temperature | -40℃ to 80℃ |

| Protection | Short Circuit Over Voltage Over temperature Over Current |

BRANDO Related Mining Strip Light

Part Number | LED configuration | Range (both side) | Power/ meter | Light Source | Working Voltage | Luminous Efficacy | Colour Temperature | Dimensions | Outer covering | IP Rating |

BO-SL60-8W-24V(B) | 60 LEDs/m | 60m | 8W | 2835 | DC24V | 90Lumens / Watt | 6500 Kelvin | L: 10000mm W: 14mm H: 4mm | Food grade silicone | 68 |

BO-SL144-17W-36V(B) | 144 LEDs/m | 30m | 17W | 2835 | DC36V | 90Lumens / Watt | 6500 Kelvin | L: 10000mm W: 14mm H: 4mm | Food grade silicone | 68 |

| BO-SL72-8W-36V(B) | 72 LEDs/m | 60m | 8W | 2835 | DC36V | 100Lumens / Watt | 6500 Kelvin | L: 10000mm W: 14mm H: 4mm | Food grade silicone | 68 |

BO-SL140-17W-110V(B) | 140 LEDs/m | 80m | 17W | 2835 | AC110V | 90Lumens / Watt | 6500 Kelvin | L: 10000mm W: 14mm H: 4mm | Food grade silicone | 68 |

| BO-SL70-8W-110V(B) | 70 LEDs/m | 120m | 8W | 2835 | AC110V | 100Lumens / Watt | 6500 Kelvin | L: 10000mm W: 14mm H: 4mm | Food grade silicone | 68 |

BO-SL140-17W-220V(B) | 140 LEDs/m | 160m | 17W | 2835 | AC220V | 90Lumens / Watt | 6500 Kelvin | L: 10000mm W: 14mm H: 4mm | Food grade silicone | 68 |

| BO-SL70-8W-220V(B) | 70 LEDs/m | 240m | 8W | 2835 | AC220V | 100Lumens / Watt | 6500 Kelvin | L: 10000mm W: 14mm H: 4mm | Food grade silicone | 68 |

1, The power supply can drive one length or different lengths within allowed maximum length by feeding

light both ends.

2, To minimize the voltage drop and keep light consistency, position power supply nearest to the power feed end of LED strip light and keep the power line as short as possible.

None